BRoof(t4) Testing & Certification for Liquid Roofing Systems: What Contractors and Customers Need to Know

Learn how BRoof(t4) certification ensures fire safety and compliance for liquid roofing systems, benefiting both contractors and end users.

We value your privacy

Our website uses cookies to enhance your experience. By continuing to use our website, you are agreeing to our use of cookies. Necessary cookies are always enabled. You can read more about our Cookie Policy in our Privacy policy

We value your privacy

Strictly Neccessary

Essential cookies enable core website functionality, such as secure logins and preference settings, without tracking personal activities or collecting data for ads. They ensure the site's proper operation and legal compliance, remaining always active

Preferences

Preference cookies enhance your browsing by remembering settings like language and regional preferences, tailoring the site to your needs without tracking activity across other websites

Statistical

Statistics cookies gather anonymous data on site interactions and page visits to help improve functionality, ensuring a smoother user experience without personally identifying users

Marketing

Marketing cookies are used to identify visitors across different websites, such as those operated by content partners or ad networks. These cookies allow companies to build a profile of a visitor’s interests and preferences, enabling the delivery of personalized ads that are relevant and engaging on other websites.

Cookies are small text files stored on your computer by websites you visit. They help users navigate websites efficiently and enable certain essential functions.

Cookies necessary for the website to function properly can be set without your consent, while all other cookies require your approval before being used in your browser.

Additionally, we use cookies to gather data for personalizing and evaluating the effectiveness of our advertising.

For more information, please refer to the Google Privacy Policy.

You can find the list of all the cookies that we use on our website here.

What Is Fibreglass or Fiberglass?

Fibreglass (or fiberglass) is a type of fibre-reinforced plastic that manufacturers create using glass fibre. Because of this, people also refer to it as glass-reinforced plastic or glass fibre-reinforced plastic. Typically, manufacturers flatten glass fibre into sheets, arrange it randomly, or weave it into fabric. They use different types of glass to produce glass fibres, depending on the intended application.

Fibreglass or glass fibre is a reinforced plastic material that consists of woven material embedded with randomly laid glass fibres, all held together by a binding substance. Manufacturers combine fibreglass with resin to create an extremely strong and durable composite. They can supply fibreglass as a flattened sheet called a strand mat or weave it into fabric.

Fibreglass offers exceptional strength, lightness, and flexibility. Manufacturers can mould it into complex shapes, which makes it an excellent construction material. Industries widely use fibreglass in bathtubs, boats, aircraft, roofs, and many other applications.

This article explains the types of fibreglass, along with their properties and uses.

Fibreglass—also known as glass-reinforced plastic or GRP—can be sold as a raw material or used in manufacturing to produce moulded products through pultrusion or hot press techniques.

Fibreglass comes in different forms.

We can classify fibreglass based on the raw materials and their proportions into the following major types:

A-glass: Also called alkali glass, A-glass resists chemicals effectively. Its composition closely resembles that of window glass. Some countries use it as a component in processing equipment.

C-glass: Known as chemical glass, C-glass offers excellent resistance to chemicals.

E-glass: Also referred to as electrical glass, E-glass serves as an outstanding electrical insulator. Industries commonly use this type of fibreglass.

AE-glass: This type, known as alkali-resistant glass, resists alkali environments effectively.

S-glass: Also called structural glass, S-glass stands out for its superior mechanical properties.

Fibreglass comes in many forms, depending on the application, including:

Fibreglass Matting: Manufacturers supply this as a flattened sheet called a strand mat.

Fibreglass Tape: Thermoelastic fibreglass tapes consist of glass fibre yarns and provide thermal insulation. Many industries use this type of fibreglass to wrap vessels and hot pipelines.

Fibreglass Cloth: This smooth material comes in various forms, such as glass fibre yarns or glass filament yarns. It serves multiple purposes, including use in heat shields and fire curtains.

Fibreglass Rope: Manufacturers twist glass fibre yarns together to form ropes, which are commonly used for packing.

Physical Strength: Fibreglass offers a greater strength-to-weight ratio than steel, which makes it ideal for producing high-performance materials.

Electrical Properties: Fibreglass acts as an excellent electrical insulator, even at low thicknesses.

Non-Combustible: As a mineral material, fibreglass naturally resists combustion. Flames cannot spread or sustain themselves on it. It doesn’t burn, smoke, or release toxic compounds when heated.

Thermal and Humidity Resistance: Changes in temperature and humidity do not affect fibreglass. As a result, it maintains a low coefficient of linear expansion.

Organic Compatibility: Manufacturers can produce fibreglass in various sizes and combine it with a wide range of synthetic resins and mineral matrices, such as cement.

Durability: Fibreglass resists decay and remains unaffected by pests and rodents.

Thermal Conductivity: Its low thermal conductivity makes fibreglass an excellent material for construction applications.

Dielectric Permeability: Thanks to its insulating properties, fibreglass works well in electromagnetic windows.

Thermoplastic materials create effective thermal barriers for industrial gaskets. Fibreglass delivers excellent insulation, protects machinery, conserves energy, and enhances worker safety. These qualities explain why many industries rely on fibreglass:

Construction: Builders use fibreglass in house construction and flat roofing.

Transportation: Vehicle manufacturers incorporate fibreglass components—such as body parts and panels—into nearly every make and model.

Aerospace & Defence: Engineers use fibreglass to produce a wide range of products, including test equipment, ducting, and enclosures.

Beverage Industry: Bottling lines and brewing houses often include fibreglass components.

Chemical Industry: Workers install fibreglass grating mixed with resin to create anti-slip safety surfaces.

Marine Industry: Dock and marina operators use fibreglass to protect against damage from salty seawater, such as rust and corrosion. Boat builders and surfboard manufacturers also rely heavily on fibreglass for both construction and repair.

Food Processing: Facilities use fibreglass to improve slip resistance and prevent machine corrosion caused by exposure to blood and other substances.

Aquaria & Ponds: Designers use fibreglass in aquariums and water fountains to support rocks, improve circulation and filtration, and protect spray headers and lights. Many garden ponds are also built with fibreglass due to its water resistance.

Manufacturing: Manufacturers embed grit into fibreglass grates to prevent slippage in wet areas or places exposed to hydraulic fluid or oil. They also use fibreglass extensively in moulding processes.

Power Generation: Power plants use fibreglass frequently because of its non-conductive properties.

Leisure: Playground equipment manufacturers use fibreglass to build slides and other structures. Pool builders often use it to line swimming pools.

Fibreglass serves a wide range of applications and industries thanks to its lightweight nature, affordability compared to carbon fibre composites, and flexibility. It offers high strength and resists corrosion and UV damage.

Manufacturers apply fibreglass using the following processes:

Hand Lay-Up

In this process, workers manually apply sheets of fibreglass and resin to a reusable mould using a hardener. They first spray the mould with a lubricant to prevent the glass from sticking. Then, they layer the fibreglass mat until it reaches the desired thickness. Afterward, they allow the product to solidify to ensure it retains its strength. Workers can also use glass tape to reinforce the edges of the mould during this process.

Spray Operation

In this method, workers spray resin and fibreglass onto a mould, similar to the hand lay-up technique. They then use rollers to press and compact the material. Once compacted, they allow the mould to cure before removing the finished product.

Compression Moulding

In this high-volume manufacturing process, operators place a sheet moulding compound—made from long strands of fibreglass on a bed of polyester or epoxy resin—onto a heated mould inside a machine. The machine then closes, and a top force presses the compound down, wrapping it around the heated mould. Manufacturers commonly use this method to produce cold water storage tanks, low-cost structures, electrical components like meter boxes, and parts for the automotive and transit industries.

Tricel Composites leads the UK market in supplying fibreglass products and materials. With over 60 years of experience in the fibreglass industry, we continue to serve customers with expertise and reliability.

We specialise in the following product ranges:

At Tricel Composites, we have everything you need for your fibreglass projects! Plus, we provide fast, nationwide delivery across the UK and Ireland.

Learn how BRoof(t4) certification ensures fire safety and compliance for liquid roofing systems, benefiting both contractors and end users.

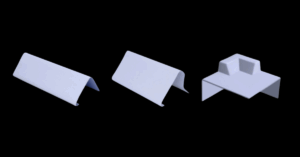

Boost your flat roof’s performance and appearance with the perfect GRP trims. Get expert advice and top product tips in our complete guide.

Roofing resins like Original GRP, HPX, MultiFlex, Polyurethane, and Acrylic offer unique benefits for residential and commercial properties. Learn about the advantages, applications, and features of each resin type to choose the best option for your roofing needs.

Upgrade your roof with quality materials for lasting performance and appeal. Explore the advantages of fibreglass kits. Read the full article now.