Aropol M105 Polyester Resin

Aropol M105 Lloyd’s Approved Polyester Resin

About Aropol M 105 TBR Lloyd’s Approved Resin

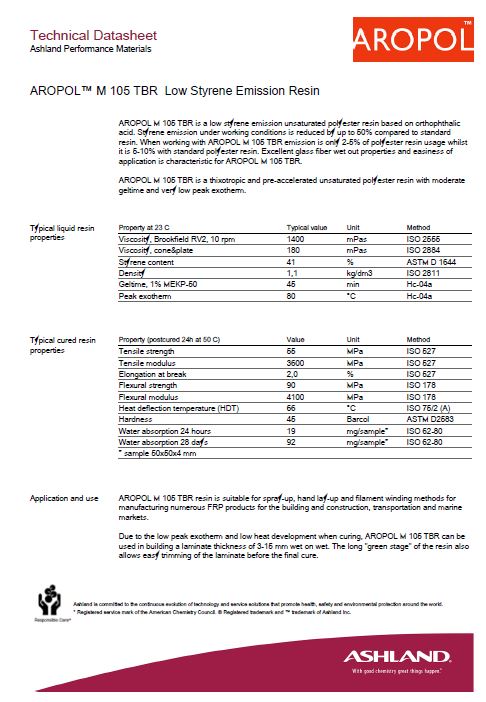

Aropol M 105 TBR, a polyester resin with low styrene emissions, comes from the well-respected composites manufacturer, Ashland. It is an unsaturated polyester resin based on orthophthalic acid. Lloyd’s Register approves this resin, making it suitable for boat construction. It also meets the requirements of ISO 12215-1, the industry standard for small craft construction.

In terms of styrene emission, this resin performs very well compared to many standard polyester resins, reducing styrene emission by up to 50%. Emission testing on Aropol M 105 TBR shows 2-5% of polyester resin usage, while standard polyester resins may have up to 5-10% emission rates.

Another benefit of this resin is its fast wet-out properties, making it very easy to work with. This resin is pre-accelerated and only requires a catalyst to start the curing process. Metox catalysts are the standard range of hardeners used with this resin. Gel time for this resin with 1% MEKP at 23 degrees Celsius is 45 minutes.

Applications of Aropol M 105 TBR

You can use the Aropol M 105 TBR polyester resin for hand and spray lay-up applications. Due to its low peak exotherm and low heat development when curing, it builds laminate thicknesses between 3 and 15mm (wet on wet).

Storage of Crystic Aropol M 105 TBR Polyester Resin

Store the polyester resin in a cool, dark place, indoors away from UV exposure. Ideal storage temperatures are under 20 degrees Celsius. The shelf life of this resin is 6 months.

Place your Next Resin Order with Tricel Composites

Tricel Composites offers many resins for distribution to our customers throughout the UK and Ireland. We have solid relationships with leading global composite manufacturers, allowing us to bring you the best resins at unbeatable prices.

If an extensive product range and great prices aren’t enough, our team of experienced composites account managers can advise you on the best technical processes and ensure you get maximum efficiency from your products.

Get in touch with us today for a quote on your next order.